Our Production Capabilities

24 Hours A Day 7 Days A week, Non Stop Production Of Polythene Films, Bags & Covers

Extruding, Printing, Converting and Recycling entirely on our single 100,000+ square foot purpose built production site allows us to supply our customers with high quality polythene products at the most competitive prices in the UK.

Polymer

Elite Plastics source a huge range of polymers from all over the world in order to achieve our excellent variety of polythene blends for products. With the primary raw material for polythene products being oil based polymer it is an industry where product prices regularly fluctuate, due to our large warehousing facilities and silos on-site we are capable of storing thousands of tonnes of polymer at any one time, this allows us to source our polymer when the market is right. This ability helps to ensure we remain one of the most competitive polythene manufacturers in the UK by passing on these savings to our customers.

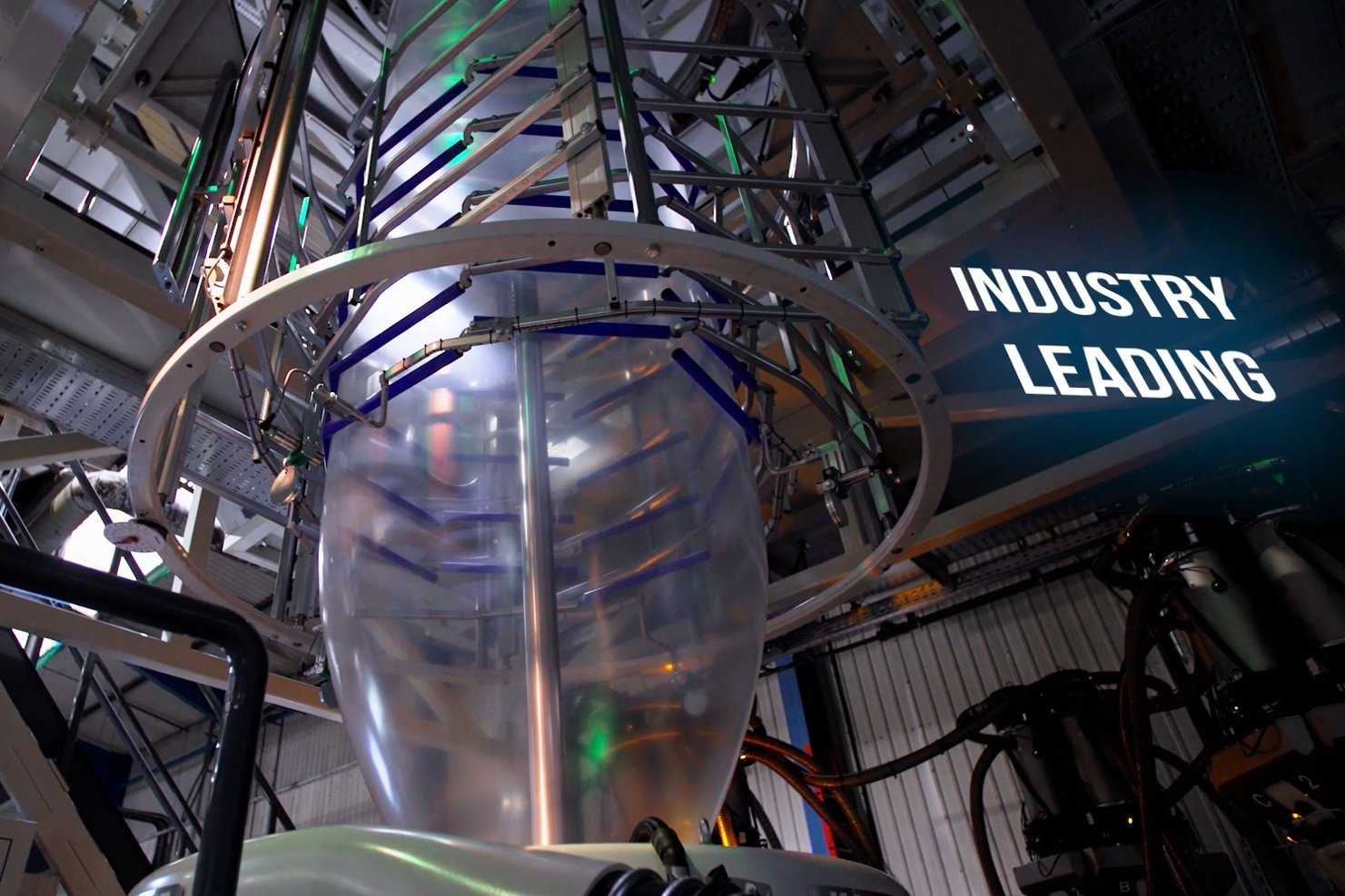

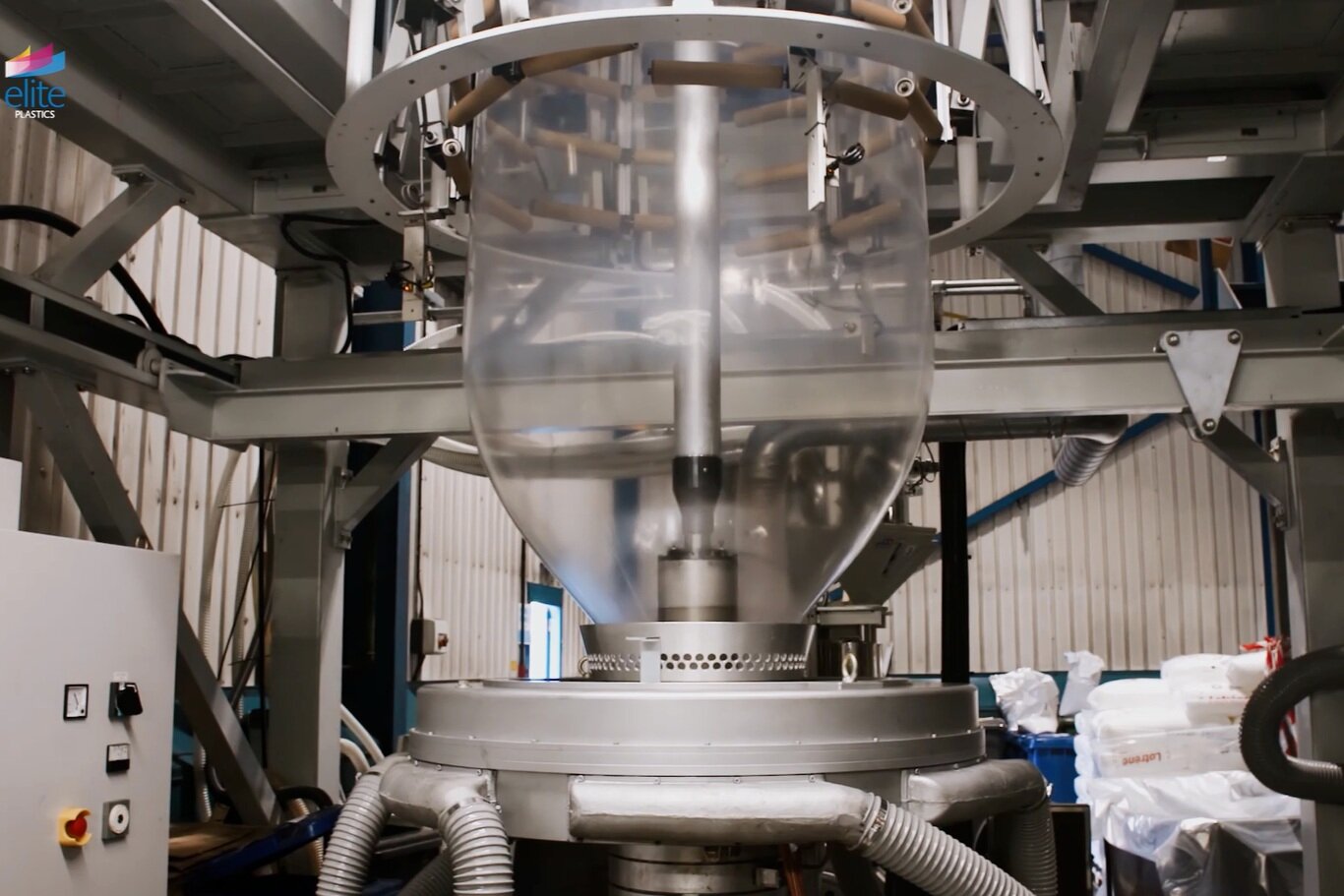

Extrusion

Our large force of extruders run 24 hours a day 7 days a week giving us the ability offer our customers low lead times and an excellent service. Our extruders operate out of two purpose built large extrusion halls optimised for polythene production. We have ensured that we have one of the most diverse extrusion forces in the UK giving us the capability to produce the complete range of polythene films, from narrow to wide width extruders, specialist sack extruders that allow us to produce the best quality polythene sacks in the country, plus more. When it comes to polythene extrusion Elite Plastics is an industry powerhouse.

Operating both in-line and out of line printers we have among the top polythene printing capabilities in the UK. Our in-line printers are fitted to every extruder that we operate. It allows us to print simple designs such as warning notices or company logos very cost effectively. Our on-site purpose built print-shop has three printing presses with the capabilities of printing up to 6 colour designs, excellent for company or product branding, our print origination team will also work alongside you through every step of the process from print design to final approval and production ensuring an excellent service and product.

Conversion

With our vast array of state of the art conversion lines we have the full range of capabilities. We can convert bags and covers either loose or perforated on a roll. Despite converting hundreds of millions of bags and covers each year we strive to ensure that every one meets the high standards that our customers expect. Our other conversion capabilities include lip and strip for products such as mailing bags. Punched out handle bags, grip seal bags, mini grip bags, wicketted bags and much more. Our diverse conversion range allows us to meet the vast majority of customer requirements so please enquire.

Technical, Storage & Distribution

Due to high service level requirements of our customers, our impressive production site is coupled with equally impressive lab testing and warehousing facilities. It gives us the capability to offer our customers a technical, stock and deliver service with the option to also manage your stock levels in a way that suits you to eliminate any risk to your company of ever running out of polythene. With the ability to despatch on the same day as call off, goods can be delivered next day giving our customers an unparalleled level of service. Elite Plastics distributes it's polythene across all of UK & Ireland while also exporting to Europe and further afield.

Renewable Energy & Recycling

Elite stands at the forefront of the industry when it comes to it’s environmental credentials. The company has an ambitious Net Zero target and has made significant investment in this area which includes a large solar installation on the roofs of two of our production halls, further investment in state-of-the-art energy monitoring and management tools and software to increase energy efficiency. Investment in brand new state-of-the-art energy efficient production lines whilst also retrofitting existing lines with energy reduction technologies. Elite has achieved recognition and has been nominated for Sustainability Initiative of the Year at this years Plastic Industry Awards.

Elite also operates a 24/7 recycling operation on-site to eliminate any plastic waste and creating closed loop recycling solutions for our customers.