Elite Wins Inaugural Sustainability Initiative Award At The Plastics Industry Awards

/Jane Salmon and Josh Salmon collect the Sustainability Initiative of the Year Award on behalf of Elite Plastics

Elite Plastics has won the inaugural ‘Sustainability Initiative of the Year’ award at the recent Plastics Industry Awards, which took place in London on November 17.

Elites new solar panel installation

Now in its 22nd year, the Plastics Industry Awards is dedicated to rewarding innovation and exceptional performance and this year, it introduced the ‘Sustainability Initiative’ award to recognise companies that are excelling in making the plastic industry more environmentally friendly.

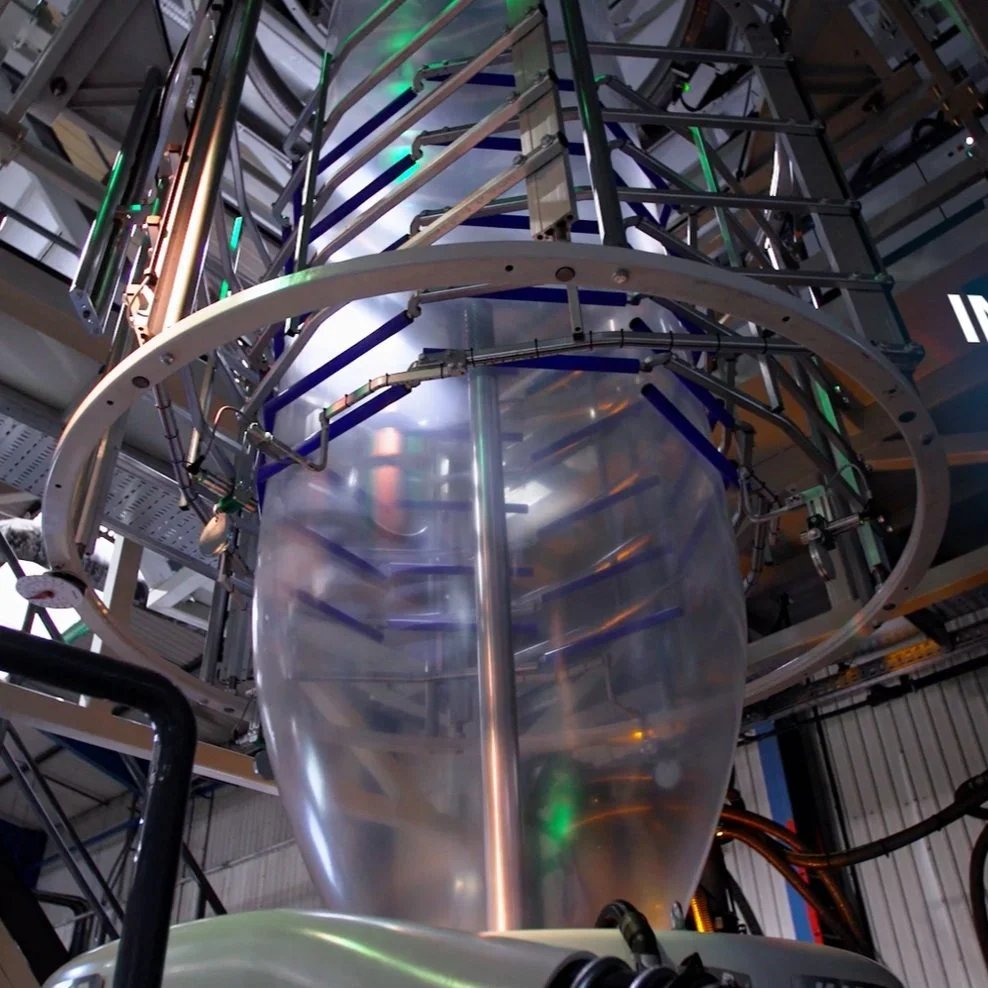

ELITES new state-of-the-art co-extrusion line

Elite Plastics is one of the UK’s leading, family-owned extrusion companies, specialising in extrusion, printing, conversion and recycling of polythene films, bags and cover packaging products.

Josh Salmon, Director at Elite Plastics, was on hand to collect the award alongside his mother Jane Salmon. He said: “We are ecstatic to have won this award. It’s a great feeling, to have our efforts and investments recognised by the industry. Sustainability is a key part of our approach at Elite and we intend to work alongside our customers to ensure that we can help them to meet their own sustainability goals, too. Winning this award demonstrates how much we have achieved so far at Elite and I’m really proud of everyone’s efforts.”

Elite has placed a clear focus on achieving its sustainability targets, which include a large Solar PV installation on the roof of the company’s two extrusion halls and a multi-million-pound investment in brand new state of the art production lines optimised for energy efficient production.

The solar installation was commissioned in March 2023 and covers the company’s two large extrusion halls. The installation is estimated to generate 220,000kWh of electricity each year, reducing total emissions by 43.2 tonnes of CO2 each year. This is equivalent to the emissions produced by a car travelling 121,551 miles. Since installation, the solar panels have powered nearly 10% of the site’s production operations and during daytime hours the site can be operating from 30%+ solar power.

The PIA judges were "hugely impressed by the current initiatives and future predictions" and noted: "Family-owned Elite Plastics has placed sustainability at the core of every aspect of its business. Elite has established itself as a sustainable and technological leader through continuous investment and innovation"

Elite has also invested heavily in brand new state of the art production lines optimised for energy efficient production, significantly reducing the energy consumed per kg of polythene extruded. They have also installed lines configured to be optimised for recycled material incorporation into technical products, with the aim to create a circular economy for recycling post-consumer waste back into the blends.

Other sustainability initiatives at Elite include, but are not limited to:

· The formal announcement of the company’s Net Zero Carbon Strategy which is maintained, reported, monitored, tracked and run through an online portal;

· Investment in a new recycling line, doubling the site’s current recycling capacity, which will significantly increase the company’s closed-loop, circular economy efforts;

· Investing in site-wide electric forklift trucks, eliminating gas and diesel forklifts in the company’s operations;

· Site-wide LED lighting project;

· Installation of a comprehensive energy management and data monitoring system for all extrusion lines to optimise and reduce energy consumption. This allows Elite to monitor the energy consumption per kilogram for every customer product that is extruded, allowing customers to use the data to prove that their products carry a reduced carbon footprint per tonne.

See link below to the PIA website:

https://www.plasticsawards.com/plasticsindustryawards2023/en/page/winners-2023